Vacuum Dehydration Oil Purification System (VDOPS)

When You Need Your Oil to Be Absolutely Clean and Dry

Recirculating your hydraulic and/or lube oil with a Vacuum Dehydration Oil Purification System (VDOPS) will help you maintain optimal fluid cleanliness in your system, extending the life of your rotating equipment and critical component parts, minimizing downtime and saving you money.

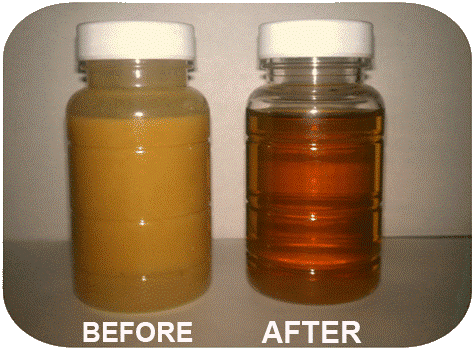

Water Removal

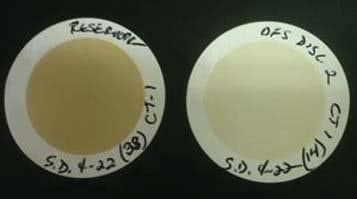

Contaminated ISO 32 Turbine Oil - emulsified water with free water at bottom

Filtered Oil - sample water less than 20 PPM

Rental Fleet of Systems

Available For Quick Shipment

Liquid Handling Specialists keeps a large rental fleet of vacuum dehydrators of all sizes ready for emergency mobilization anywhere in the world. We have the largest and best maintained fleet of vacuum dehydrators in the industry today, and experienced field service technicians can either walk you through easy start-up procedures over the phone or accompany the system to your jobsite to help with start-up, commissioning, and training.

(770) 449-4000

Model Selection Key

Vacuum Dehydration Oil Purification System

Flow Rate:

1 = 1 GPM

3 = 3 GPM

5VFD = 5 GPM Variable Flow

10VFD = 10 GPM Variable Flow

15VFD = 15 GPM Variable Flow

20VFD = 20 GPM Variable Flow

30VFD = 30 GPM Variable Flow

40VFD = 40 GPM Variable Flow

50VFD = 50 GPM Variable Flow

100VFD = 100 GPM Variable Flow

Filtration:

413X = OFS-413X (Series) Cartridge

820X = OFS-820X (Series) Cartridge

840X = OFS-840X (Series) Cartridge

BF#2 = OFS-BF#2 (Series) Bag

Heater Rating:

3 W = 3 kilowatt

6kW = 6 kilowatt

17kW = 17 kilowatt

33kW = 33 kilowatt

48kw = 48 kilowatt

66kW = 66 kilowatt

*Optional Equipment:

4PLL = 4-Point Lifting Lugs

4PLS = Cage Structure with 4-Point Lifting Lugs

AWD = Automatic Water Drain

DMI = Digital Moisture Indicator

DPM = Digital Particle Monitor

EHC = Wetted Components Compatible with

Fyrquel EHC Fluid

SS = Stainless Steel Wetted Components

Electrical Requirement:

120 = 120V / 1Ph / 60Hz

200 = 200V / 1Ph / 50Hz

220 = 220V / 1Ph / 50Hz

220V / 1Ph / 60Hz

220V / 3Ph / 50Hz

220V / 3Ph / 60Hz

380 = 380V / 3Ph / 50Hz

400 = 400V / 3Ph / 50Hz

415 = 415V / 3Ph / 50Hz

480 = 480V / 3Ph / 60Hz

575 = 575V / 3Ph / 50Hz

Electrical Rating:

N4 = NEMA 4

N7 = NEMA 7 Explosion Proof

Class 1 Div. 1 or Class 1 Div. 2

Seal Material:

V = Viton

B = Buna N

Custom Options:

Z = Custom

Equipment

(Specified)

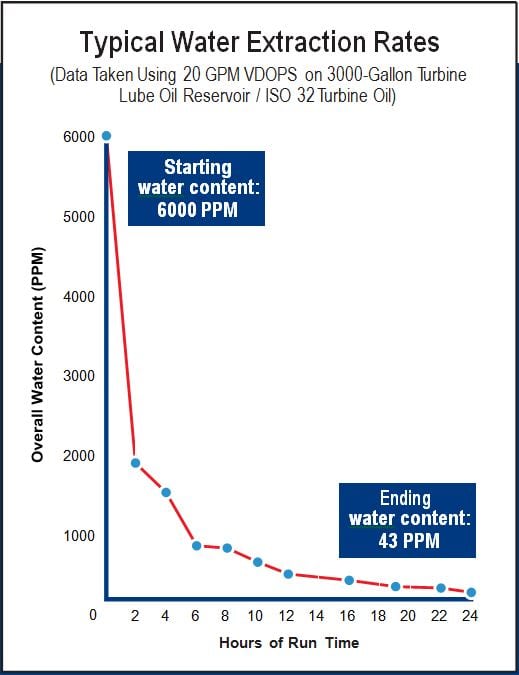

Highest Water Extraction Rates in the Industry

Alarm indicators with automated system shut-off – enables unattended operation for 24/7 service

Permanent dispersion media – provides maximum surface area for high water extraction rates; eliminates need for costly coalescer element change-out

Dry running “claw” style vacuum pump – very durable and reliable in wet oil applications; requires very little maintenance while providing long life

Phase reversal switch

Digital temperature controller – enables operator to set optimal oil temperature

Variable frequency drive – gives system versatility across a wide range of applications

Inlet solenoid valve – for fail-safe isolation

High Performance Purification

The harmful effects of water, entrained gases particulate, and varnish contamination in lubrication and hydraulic oils have been well documented. By removing all water contamination and entrained gases, VDOPS helps maintain the oil’s original viscosity, ensuring its optimal performance and extending its life as a lubricant.

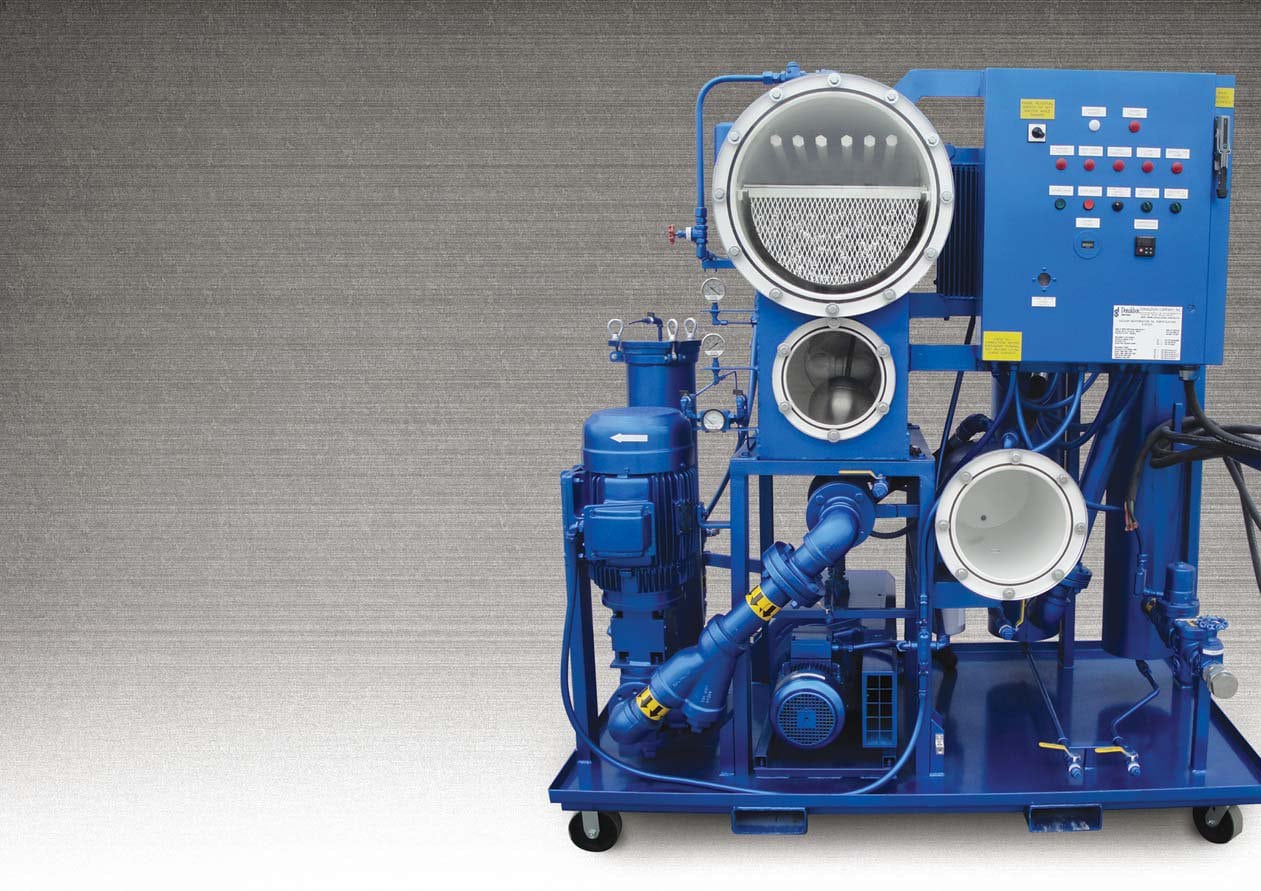

50 GPM NEMA 4

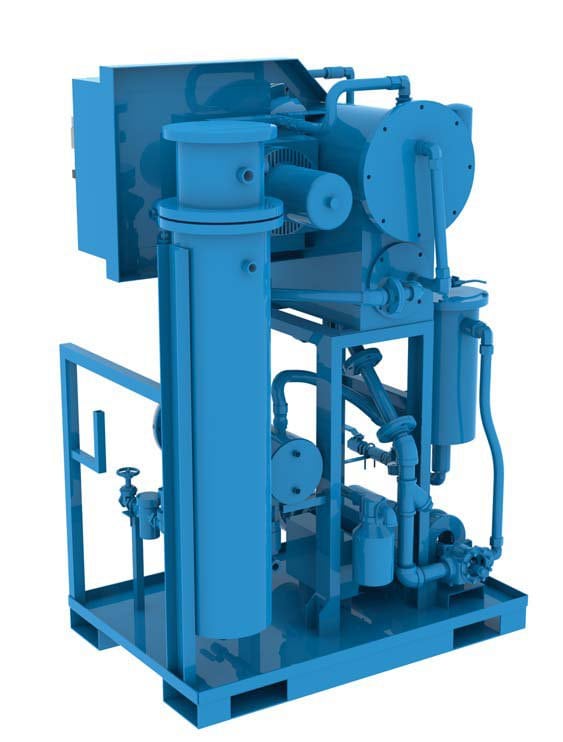

5 GPM NEMA 7

3 GPM NEMA 4

VDOPS units are available in a wide range of configurations and flow rates to adequately handle virtually any application.

"OFS has been a preferred supplier of filtration equipment and vacuum dehydrators for the Chevron ISOCLEAN® Program now for five years, and not only does their equipment give unmatched performance in terms of water and particulate removal, their company gives us the kind of customer support, customized quick response, and service that we need in today’s fast-paced and competitive business environment."

Paul Sly, ISOCLEAN® Program Coordinator, Chevron Lubricants

Effective for Use On:

-

ISO 32 Turbine Lube Oil

-

Hydraulic Oil

-

Paper Machine Oil

-

Gear Oil (ISO VG 150 – ISO VG 680)

-

Compressor Oil

-

EHC Fluid (Fyrquel® and other phosphate esters)

-

Bio-Diesel

-

Waste Oil (used engine oil)

-

Heavy Fuel Oil and Bunker Fuel

Elevated vacuum tower – provides gravity flow to oil discharge pump for reliable performance on high viscosity oils

Filter housing – holds high efficiency pleated microglass filter element rated Beta(c) > 1000 per ISO 16889

Positive displacement gear pump – with Viton® mechanical seal

Heavy duty skid base with spill containment lip, forklift slits (and casters)

Low watt density heater – with outer insulation and 2 thermocouples for added safety (process and high limit)

Inlet basket strainer – for pump protection

All hard piping – no hoses

Because of its unique vacuum tower design and high CFM vacuum pump, our Vacuum Dehydration Oil Purification System (VDOPS) gives the highest water extraction rates available in the industry today. We build Vacuum Dehydration Oil Purification Systems (VDOPS) in a wide range of process flow rates for optimal performance on almost any application. A general rule of thumb to use is 1 GPM flow rate for every 100 gallons of reservoir capacity, so we build VDOPS units in the following process flow rates: 1 GPM, 3 GPM, 5 GPM, 10 GPM, 15 GPM, 20 GPM, 30 GPM, 50 GPM, 100 GPM Our experienced sales and technical support personnel will help you select the correct system for your specific application depending on all of the unique conditions at your plant. In addition, because we use only the highest quality components in the overall design (Gardner Denver vacuum pumps, Siemens PLCs, Gems low flow switches, Watlow heaters, Viking gear pumps, and Baldor motors), our VDOPS is the most reliable, durable, and user-friendly system available in the industry today.

Varnish Removal Options

Varnish contamination in the turbine lube oil systems of gas turbines has recently become a major concern for maintenance personnel. For this reason, Oil Filtration Systems, LLC now offers a “varnish removal” option on all of our Vacuum Dehydration Oil Purification Systems (VDOPS). By diverting the flow of turbine oil through specially formulated granular adsorbent media, soluble varnish can be effectively removed from the oil, eventually resulting in the removal of varnish that has plated out on critical components, including servo valves in the speed control system.

Left sample – CT-1 Main LO Reservoir (collected off return header):

MPC = DE 38 ABNORMAL Right sample – CT-1 OFS Varnish

Mitigation System (collected from sample port on system):

MPC = DE 14 NORMAL

Employs Most Efficient Filter Elements

High-efficiency filter elements for particulate removal from all mineral-based and synthetic hydraulic, lubrication, dielectric, and turbine oils. Our elements are constructed with the highest quality micro-fibrous glass filtration medias available. Our filtration technology, incorporates medias that are layered to achieve optimal performance characteristics. Our elements are suitable for use in the most demanding applications, and they are designed and tested to provide the highest level of efficiency with the maximum dirt holding capacity. All OFS filter elements have particulate removal efficiencies of Beta(c)>1000 (99.9% for the stated micron size), which is based on ISO 16889-1999 testing standards. They are available in a wide range of micron sizes to suit virtually any application (2.5, 5,7,12, and 22-Micron).